Most top load washers will exhibit some activity, i.e. fill, hum or click, no matter what is internally broken. With few exceptions, the only reason one would be completely dead is no power coming in through the line cord. This is easily traced by testing the outlet with a light and then checking the cord itself.

On computerized washers a dead machine often means a bad computer. All of this design have a diagnostic mode that is key to testing. If you are unable to enter diagnostic again the computer or the touch pad has failed and needs to be replaced. Power surges and lightening can cause such failures.

Exceptions

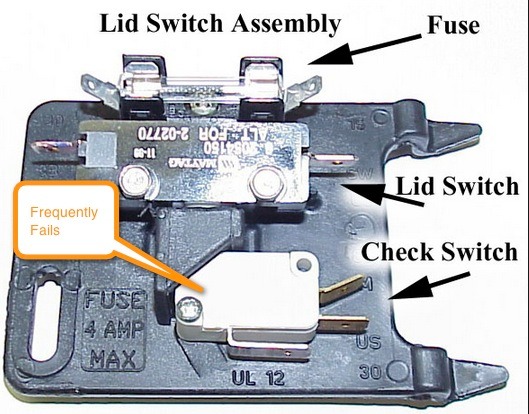

One old series of the Maytag Dependable Series did have a fuse in the console, tied to a little white check switch.

A subsequent series completely died if the lid switch was bad.

This Maytag Switch Kills the Washer

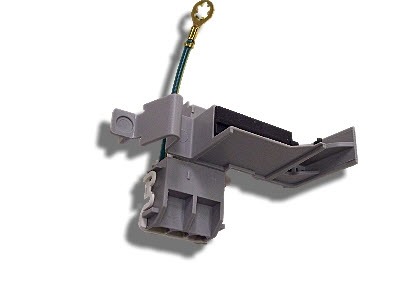

The newest style Whirlpool Direct-Drive also dies with a bad lid switch; this is the one operated by the hinge arm.

This Whirlpool Switch Also Kills the Washer

I suppose this is a reflection of our being super safety conscious. We are not even allowed to watch a machine fill anymore. If power is confirmed and the lid switches check OK, it is likely a bad timer. This means a schematic check out.

Whirlpool Switch Location