Or Stops Halfway Through The Cycle or Fills Slowly

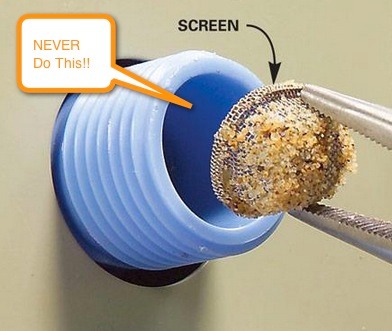

Fortunately, this is an easy problem to solve. Most solutions involve the fill valve. It needs to be flushed of replaced. Either it is clogged or faulty. Clogging always occurs on the cold side. Why is that? It is because sediment or dirt in the water supply has a chance to settle out in the bottom of the hot water heater and does not get to the washer.

Guaranteed to Result in a Flood

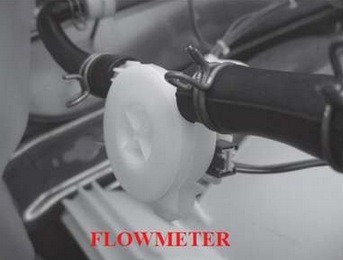

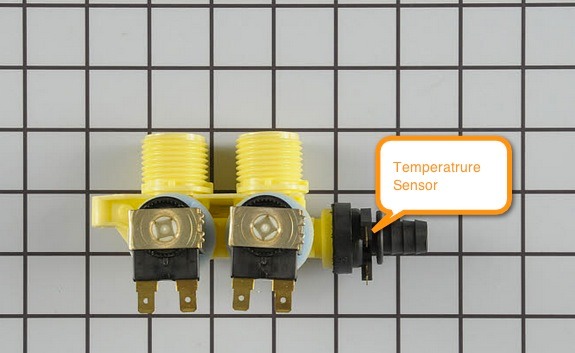

So what happens? Most machines wash with warm and drop back to cold for the rinse cycle. If the cold side of the valve is clogged little or no cold will flow and the washer will sit forever waiting for water. "My washer stops mid-cycle!" Computerized washers monitor the flow of water and generate error codes if the correct flow is not measured. Computerized machines not only check water flow they also check water temperature. Reversed hot and cold hoses will generate error codes by confusing the computer.

Use a baster or turn on the fill hose for a second and flush out the grit. If that does not help replace the valve.

A Whirlpool Duet Flow Meter Measures Gallons Per Minute

Temperature Sensing Thermister Built into Valve

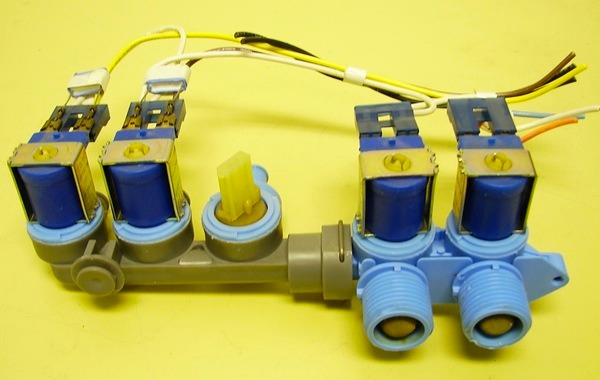

Older machines use a simple two-coil valve but front loader and energy efficient top loader valves are complex and expensive. Injector systems need several fill lines and thus numerous valves to flush in soap and bleach.

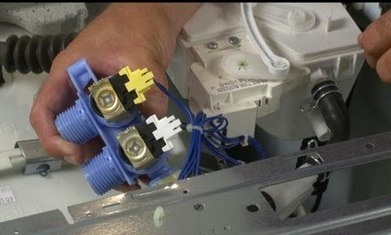

Complex Valve

Front loaders have their own proprietary valves; there is no interchange between brands like on older washers.

Samsung Detergent Drawer

Back of Whirlpool Duet Drawer and Water Valve

The diagnostic cycle of new washers allows you to remotely select each coil of the water valve and test it by turning it on and off. This is very helpful if a washer has multiple valves, any one of which may cause error codes or shut down the cycle. It is far faster and easier than connecting a temporary test cord.

Neptune Complex Valve