Noisy dryers are a real money maker. Rollers and idlers go bad on all brands with great frequency. They are easy to fix and should be truck stock items.

Reason other than support rollers:

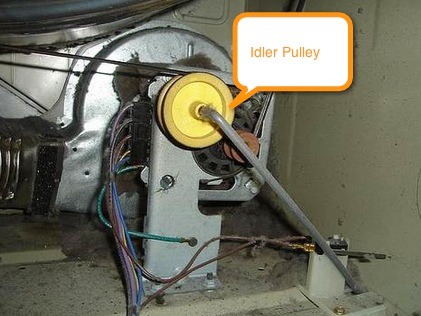

1. First, run the dryer and listen to the speed of the noise. Is it high speed, like the motor, or is it timed with the rotation of the drum? This points you in the right direction. Drum bearings and drum damage repeat much slower. Cabinet damage, like a collaped top will only make noise once a cycle. A bad belt idler is high speed.

GE Rear Drum Support

GE Idler Makes a Loud Squeel

Electrolux Rear Bearing

GE Front Bearing Wears Out and Make Grinding Noises

2. Loose flipping baffles or coins caught in a baffle occur but are easy to fix.

Dryer Baffle

3. Timer motors actually can get quite loud sometimes. Put your ear close by.

4. A drive motor occasionally will squeel and fool you into thinking an idler roller is bad. To test, run the motor with the belt off

5. Occasionally lint will pile up on the blower blades and made a high speed rumbling noise.

Trick of the Trade: The Whirlpool blower is famous for getting jammed by a felt seal (a piece of the motor shaft seal) that gets stuck between the blower and the housing. This felt can make very unusual and misleading noises. Many a tech has put in a new motor to find this mysterious piece of lint all balled up behind the blower.

Whirlpool 29" Motor Replacement